Build Your Own Gang Sheet

Build Your Own Gang Sheet

Collapsible content

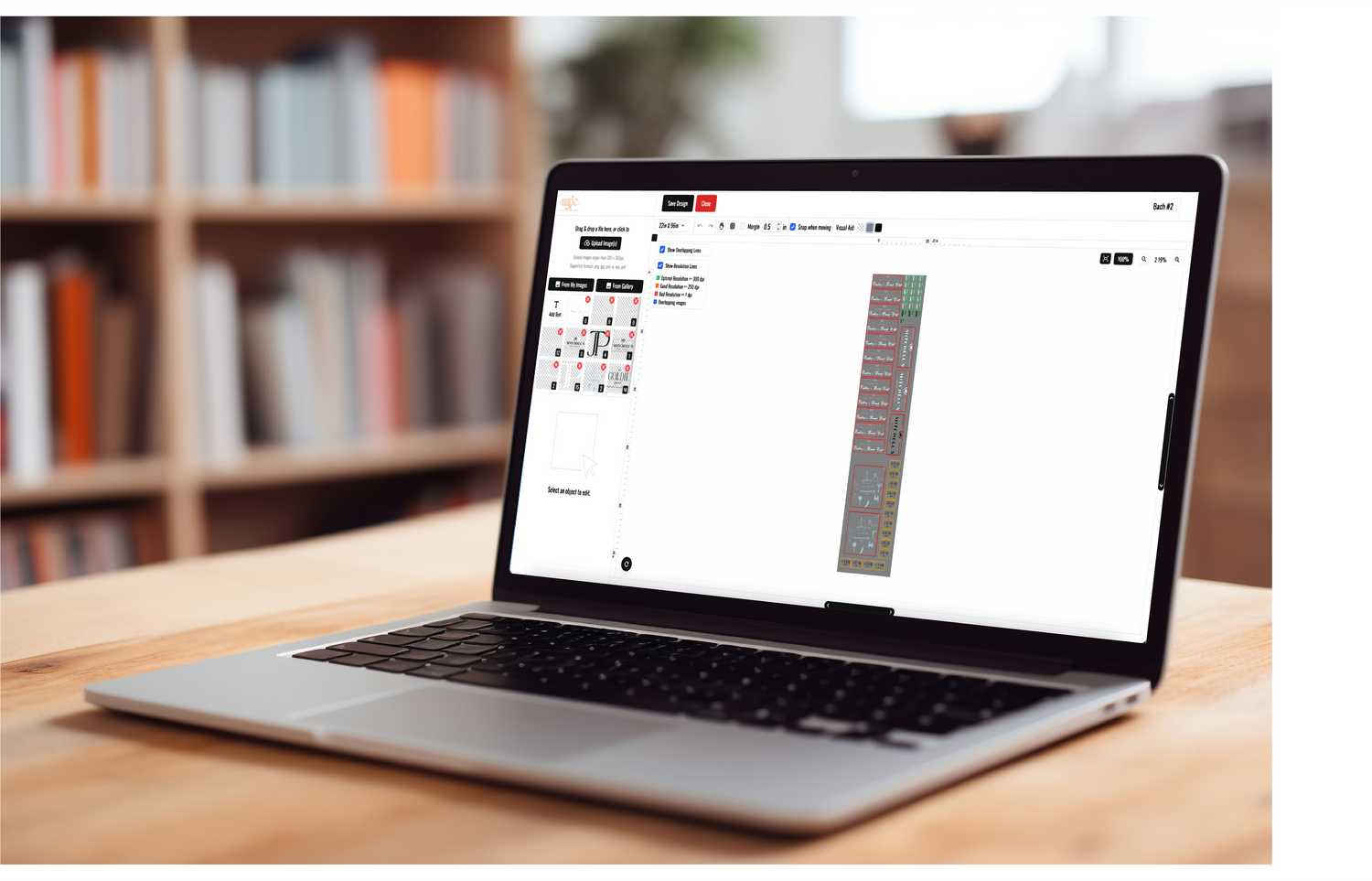

What is the Gang Sheet Builder

Our Gang Sheet builder eliminates the guesswork associated with creating Gang Sheets. Not only does it save you the expense of purchasing costly design software, but more importantly, it spares you the time and effort of learning to use such software effectively to produce acceptable Gang Sheet files. Our Gang Sheet builder comes equipped with templates specifically configured to work seamlessly with our printer. It also offers a wide range of user-friendly options for preparing your artwork. Say goodbye to the uncertainty of Gang Sheets and begin utilizing our builder today!

How to Build a Gang Sheet

Check out our Gang Sheet Builder tutorial video above!

Click the "Build your own Gang Sheet" button to begin.

- Once the designer opens:

- Choose to start a new sheet, open a historical sheet, or auto-build

- Upload your artwork or use designs from the Gallery to design your sheet.

- Adjust Sheet and Design Size as necessary (Ensure designs do not overlap or exceed the edges).

- After adding all designs, save and add your gang sheet to the cart. It will be saved for future use if desired. Then, you can exit or create another sheet.

- Your gang sheet will be added to the cart, where you can view and edit it.

DISCLAIMER: The background removal and auto-build tools are helpful but not always 100% perfect. Please ensure you are satisfied with the result before submitting. We are not responsible for undesired results from the use of these tools.

Gang Sheet Artwork Requirements

- Ensure your artwork is "Ready To Print" before submission. Orders with substandard artwork may be canceled, and you'll receive a store credit to reorder once your images is fixed.

- For optimal results, aim for a 300 DPI resolution. Lower resolutions may result in loss of quality and unclear or jagged prints.

- Artwork quality significantly impacts print quality. If your image appears blurry when zoomed in, it will print blurry.

- Crop your images before submission to ensure accurate sizing. Failure to do so may result in order cancellation, with a store credit issued for resubmission after image correction.

- Transparent backgrounds are essential for proper printing. Orders with non-transparent backgrounds may be canceled and you'll receive a store credit to reorder with a corrected image.

- We only print artwork as submitted; no alterations are made unless assistance is requested.

- We do not replace low-quality transfers resulting from low-resolution images for free. You'll need to reorder with a high-quality image at the regular price.

- Our printers use the CMYK color spectrum. Design your artwork accordingly. Additionally, colors may vary slightly from what appears on your monitor. We do not guarantee colors to match what you see on screen and will not replace transfers as a result of a slight color difference. If you have an extreme color difference please message us so we can assist you.

- We are not liable for color or quality issues arising from low-quality or bad-resolution files provided to us.

- Artwork not suitable for DTF custom transfers includes screenshots or downloads from social media/google, glowing or hazy effects, transparency or opacity effects, and super thin or small fine details. These may not print as intended or adhere properly to garments.

- By submitting Artwork to be printed by Blu Ridge Design Co you are agreeing that you have read and agree to the Artwork requirements and that you will not hold Blur Ride Design Co accountable for any unsatisfactory prints that are a result of subpar artwork submitted.

As always feel free to reach out with any questions regarding your artwork. We're always here to assist!

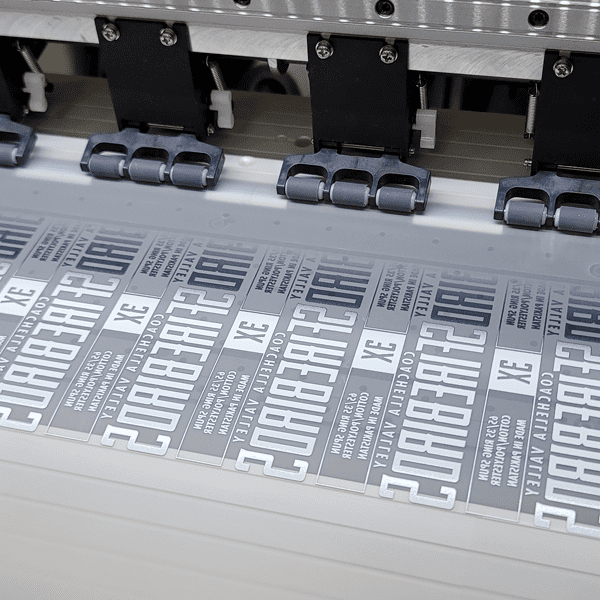

General DTF Transfer Information

DTF transfers offer versatile application, adhering seamlessly to an array of T-shirt fabrics such as 100% Cotton, 100% Polyester, and Poly/Cotton Blends. Moreover, they can be successfully applied to diverse surfaces like can cooler sleeves, pillows, canvas, polyester, leather, wood, and beyond. With a full white under base, our DTF transfers ensure complete opacity, enabling vibrant designs to pop on any colored garment. Their soft texture and exceptional durability often outlast conventional screen-print transfers, ensuring lasting quality and vivid impressions.

Turn Around Time (TAT)

Our standard turnaround time is usually 1-2 business days (Monday to Friday), excluding weekends and major holidays. However, during peak periods, our turnaround time may extend slightly. Rest assured, we strive to keep you informed by updating the current turnaround time on our shop banner.

Shipping and Processing

Enjoy complimentary shipping on all orders over $75.

Every transfer is printed to order and will be dispatched within 1-2 business days, unless otherwise specified in the current TAT banner at the top of each page.

Orders are shipped via UPS with an estimated arrival time of 2-6 days. To expedite delivery, consider upgrading to a Priority service at checkout.

For international orders, please be aware that you are responsible for any applicable duties, import taxes, or associated fees.

Transfer Pressing Instructions

Given the variability in heat presses, including temperature and pressure settings, adjustments tailored to your specific press are often necessary.

It is also important to exercise caution when pressing transfers, ensuring you are knowledgeable about your application and peeling technique.

Avoid using non-commercial grade heat presses or irons with our transfers. We recommend employing a heat gun to verify temperature and conducting a pressure test before pressing.

If this is your first time ordering from us, we recommend acquiring a few extra designs to determine the optimal settings mentioned above.

Pressing Instructions:

- Preheat the garment to eliminate excess moisture

- Align the transfer on your garment in the appropriate position glue side down.

- Temperature: 320 degrees Fahrenheit

- Time: 15 seconds

- Pressure: Heavy (8-9 manual) 60PSI Automatic

- Allow the transfer to cool to the touch for approx. 15-30 seconds before removing the clear film

- Place protective covering of your choice (Parchment Paper, Butcher Paper, Protective Pads etc.) over the design and repress for an additional 15 seconds to ensure it cures into the shirt.

- Wait 24 hours before washing or stretching the garment.

Pro Tip! Try placing a single layer of t-shirt material over the design on your second press to soften the design, increase durability, and remove shine. If you want a shiny finish, cover with a protective guard sheet or butcher paper for the final press.

Washing and Care Instructions

Washing Guidelines:

- Wait 24 hours before the initial wash.

- Turn the garment inside out before washing.

- Machine wash using mild detergent. Avoid using bleach.

- Dry using a normal dryer setting on household machines. (Lowest heat setting recommended)

- Avoid dry cleaning and refrain from using fabric softener.

- These instructions are specifically for the DTF transfer; kindly adhere to any additional garment washing instructions.

Storing Transfers:

Proper storage of DTF print transfers is essential for their longevity. To maintain optimal conditions, follow these guidelines:

- While there is no fixed shelf life for DTF transfers, it largely depends on storage conditions. We recommend using your prints within 30 days. However, under ideal conditions, they can last up to 12 months.

- Maintain low humidity levels (less than 50%) to prevent moisture from affecting the powder on the back of the images.

- Store transfers flat horizontally in a cool, dry location. This could be in an airtight container or on storage shelves, away from heat sources such as heating vents. Storing them in a closed box or container helps prevent dust accumulation.

- Consider labeling the date of receipt on your transfers to ensure you use them in order from oldest to newest. This also helps gauge their storage duration in your setup.

Disclaimer

- Our Ready to Press Library offers convenience, eliminating the need for you to create or purchase PNG files elsewhere for printing. However, please note that this does not guarantee that your transfers will always arrive pre-cut and trimmed. We reserve the right to determine whether to cut an order or ship it as a sheet, unless prior coordination is made.

- The quality of the print greatly depends on the quality of the artwork. If the artwork appears blurry on your screen when zoomed in, it will appear blurry when printed. It is your responsibility to ensure that your artwork is print-ready. We will print what you send and cannot be held responsible for undesirable prints.

- Assistance with your images is available for an additional fee. Please message us if you need help!

- Please be aware that semi-transparent (see-through) graphics cannot be achieved in DTF printing and will result in undesirable outcomes.

- Actual colors may vary slightly from those seen on screen. DTF prints use the CMYK process (a mixture of four colors to create one color).

- DTF printing does not support fluorescent neon colors, metallics, or glows. Submitting artwork with these effects may produce undesirable results.

- We are not responsible for undesirable prints that are due to bad artwork quality.

Advantages of Gang Sheets

Two Words: Cost-Effectiveness.... Utilizing gang sheets in the production process offers a standout advantage in terms of cost-effectiveness. The strategic utilization of space on our materials not only curtails waste but also drives down overall production expenses.

For businesses like Blu Ridge Design Co. operating in the custom DTF transfer industry, this translates into a more resource-efficient approach and an enhanced bottom line.

The capability to print multiple designs on a single sheet without compromising quality enables businesses to fulfill a greater volume of orders at a reduced cost, thereby improving profitability while decreasing cost for the consumer and still delivering a top-notch products.

Tips for creating gang sheets

Master Design Software:

Spend time mastering design software to maximize efficiency when creating gang sheets. Utilize features that facilitate easy manipulation and arrangement of designs on a single sheet.

Tips for creating gang sheets

Use our Gang Sheet Builder:

Don't have time to master design software? That's ok! We have taken that burden off of our customers because we know you have more important thing's to worry about. Build your gangs without out the hassle using our Online Gang Sheet Builder!

Tips for creating gang sheets

Optimize Design Placement:

Strategically place designs on the gang sheet to minimize waste and maximize space utilization. Experiment with different layouts to find the most efficient arrangement.

Tips for creating gang sheets

Plan Ahead:

Plan ahead and gather all necessary designs before creating the gang sheet. This will streamline the process and minimize the need for revisions.